Engineering

Product design

Design Feasibility support

Moldflow

Tool design

|  |

| PRODUCT ANALYSIS | |

| DRAFT ISSUE | |

| PARTING LINE | |

| WALL THICKNESS | |

| SINK MARK | |

| VISIBLE SURFACE | |

| SURFACE FINISH |

| MOLD DESIGN ANALYSIS | MOLDING ANALYSIS |

| INJECTION MACHINE SPECIFICATION | FILLING |

| MATERIAL SHRINKAGE | PRESSURE |

| PARTING LINE | TEMPERATURE |

| GATE LOCATION AND TYPE | WARPAGE |

| MOLD LAYOUT | SINK MARK |

| INSERTS/SLIDE/LIFTER | COOLING TIME |

| EJECTION | CLAMPING FORCE |

| COOLING LINES | WELD LINE |

| VENTING | AIR TRAP |

| THIN STEEL EVALUATION |

We take initial concepts and ideas and help progress this all the way through to the finished moulded product. The one stop shop helps to reduce management costs and ensure a smooth, unbroken continuation of development.

Our technical and engineered team are specializing in injection mould manufacturing for more than 8 years. With professional and profound knowledge from a large amount of mould design work, we believe that we can meet clients' specific requirements. All our expertise and experience is put to use in designing mould for your application. Knowing well about HASCO, DME and European standard, our design engineers use advanced CAD, CAE and CAM software system to offer optimum mould design.

Engineering Assistance

1. DFM and designing, suggestion about the part structure based on the 3D parts analysis

2. Mould flow analysis if needed

3. Weekly schedule report with pictures

4. Trial samples with issues clarified, planned improvements

5. According to 2D drawing provide the trial samples inspection report

6. Moulding process parameters

Sectors

We are making molds for below areas.

Automotive

Aerospace

Motorsport

Industrial

Marine

Special projects

Common custom plastic moulds

High precision moulds

Large size moulds

Two shot moulds

Unscrewing moulds

Insert moldinh tools

High cavitation moulds

Gas assist mould

Collapsible core insert moulds

Diecasting mould

Mould type

Common custom plastic moulds

High precision moulds

Large size moulds

Two shot moulds

Unscrewing moulds

Insert moldinh tools

High cavitation moulds

Gas assist mould

Collapsible core insert moulds

Diecasting mould

Mold trial

The trialling stage of a development project is an essential element of the evaluation process as sample components are manufactured and validated, for customer approval.

Following initial tool trials, product evaluation and any required corrective actions, or minor adjustments, are carried out. Our dedicated tool trial team will look to optimise the conditions with a full evaluation of the process.

Components will be assessed by our quality department to ensure they meet the standard required. On completion of the trial samples will be submitted for customer review and approval. Agreed alternative materials can be trialled at this stage, with full inspection reports also submitted for approval.

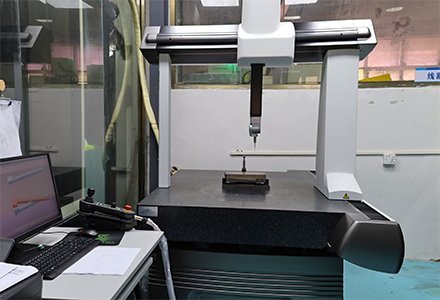

Quality

Detail determines quality, attitude determines quality.

LEMO MOULD realized high quality is one of the key points for long term cooperation, and the value of our service to assist customers to grow their business increasing. So we always invest enough to the quality control, from inspection facilities purchasing, QC people training and auditing process, to make sure a strict manufacturing process.

·Inspect workpieces at every manufacturing process, make sure it’s qualified to design spec and then to next working step.

·Special person checking material and components coming in and out schedule and actual situation.

·All material and components are as FIFO, first in and first out.

·Each mold with only one BOM list, to checking and follow the loop.

·Each electrode and mold workpiece is engraved a clear mark so it can be followed easily.

·Main steel material and components with certification of original file, and testing report, to make sure it’s qualified.

·Conducting 5W1H quality follow system, asking and investigating the problems and have a solution to avoid the problem happen again.

High quality mold is our target, accurate, careful, careful examination is our action, the good service is our tenet.

|  |

Plan + control + improvement & experience sharing = systematization of quality system

The whole staff has implemented the ISO 9001:2015 standard and strictly implemented the eight principles of quality management

|

Choose us

|

|

About Us

|

|

Our Factory

|

|

Capability

|

|

Case Study

|

|

Management

|

| COPYRIGHT @ LEMO MOULD (H.K)/(SHENZHEN) LIMITED ALL RIGHTS RESERVE

|

PRODUCTS

ABOUT US

CONTACT US

|