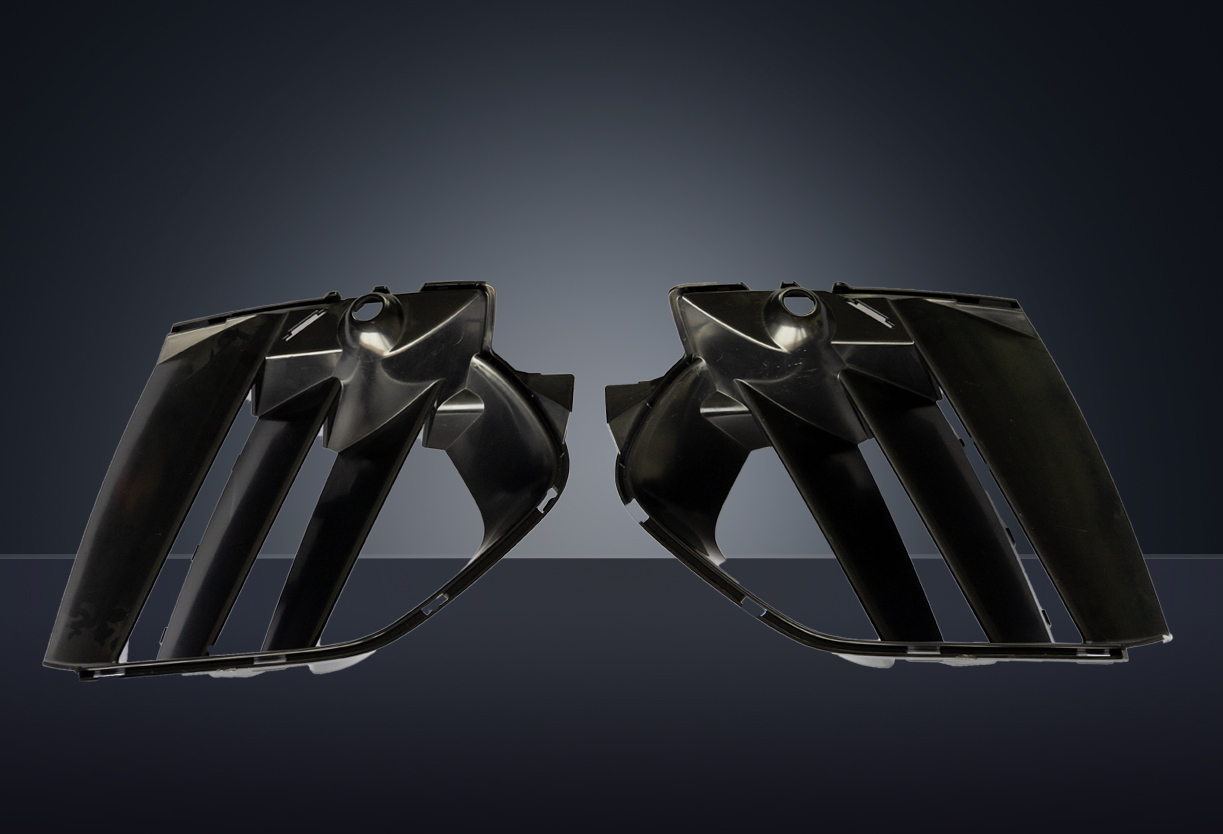

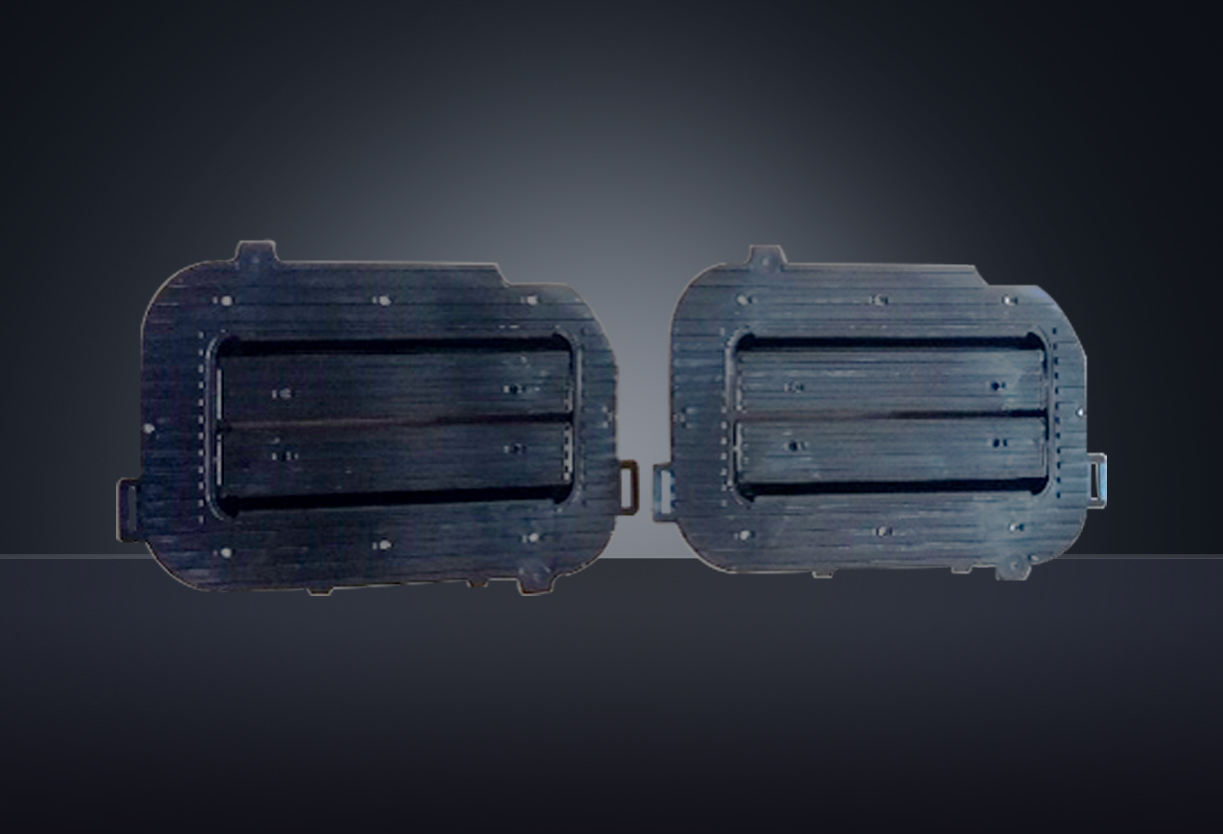

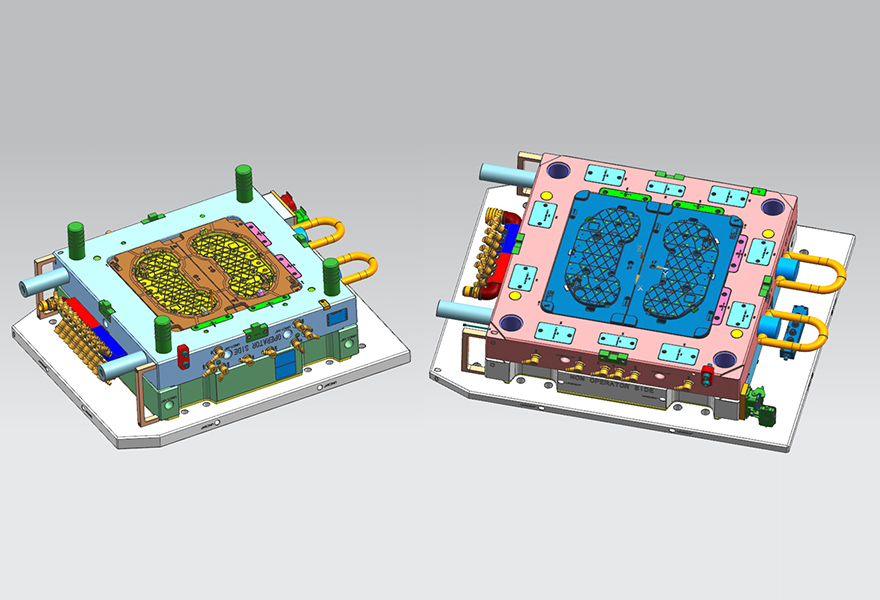

Car headlight shield

Automotive mould, high quality requirements, need to design very good gating system balance of the part, and when molding, also need to be carefull with the material data specification and use very suitable injection pressure and clamping force as far as possible, and how to prevent the sink mark. However, our professional Mold technology and rich exerienced skilled workers allow us to make production more stable, efficient and ecomomic.

|  |

|  |

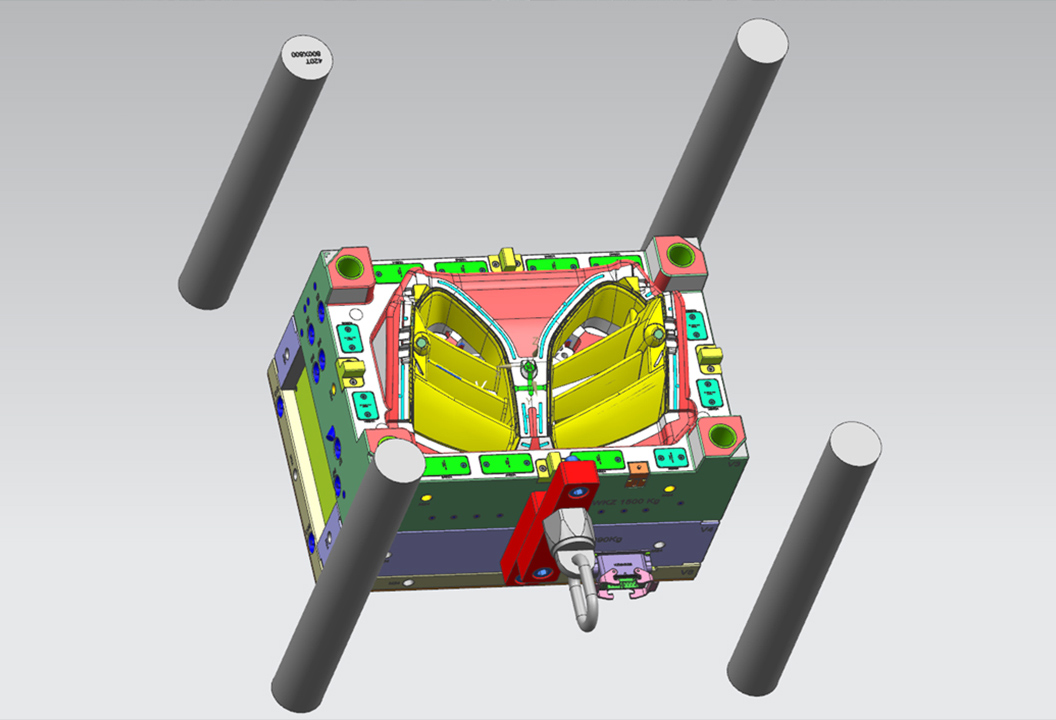

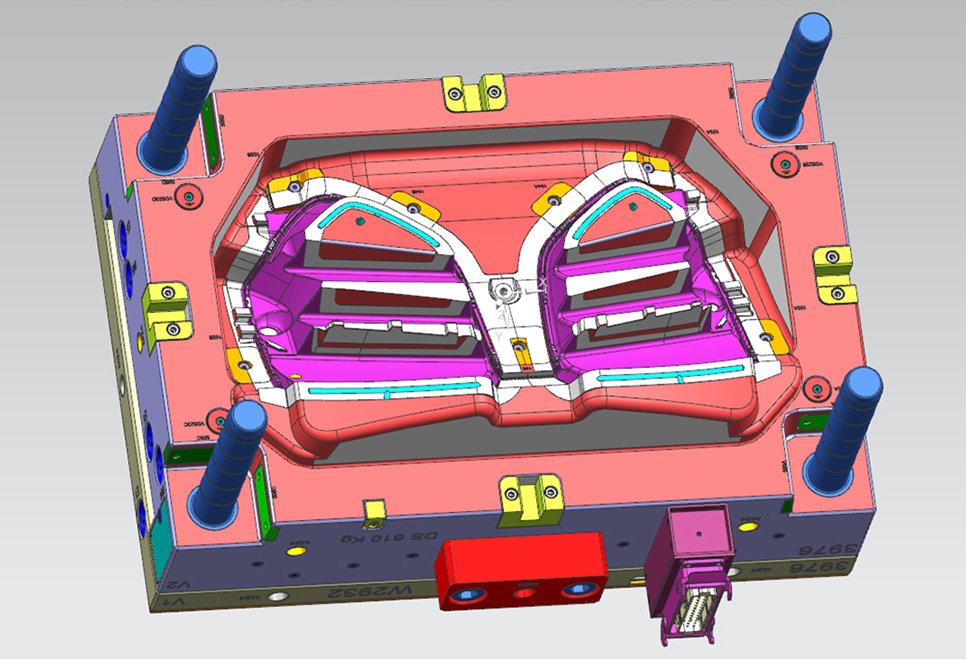

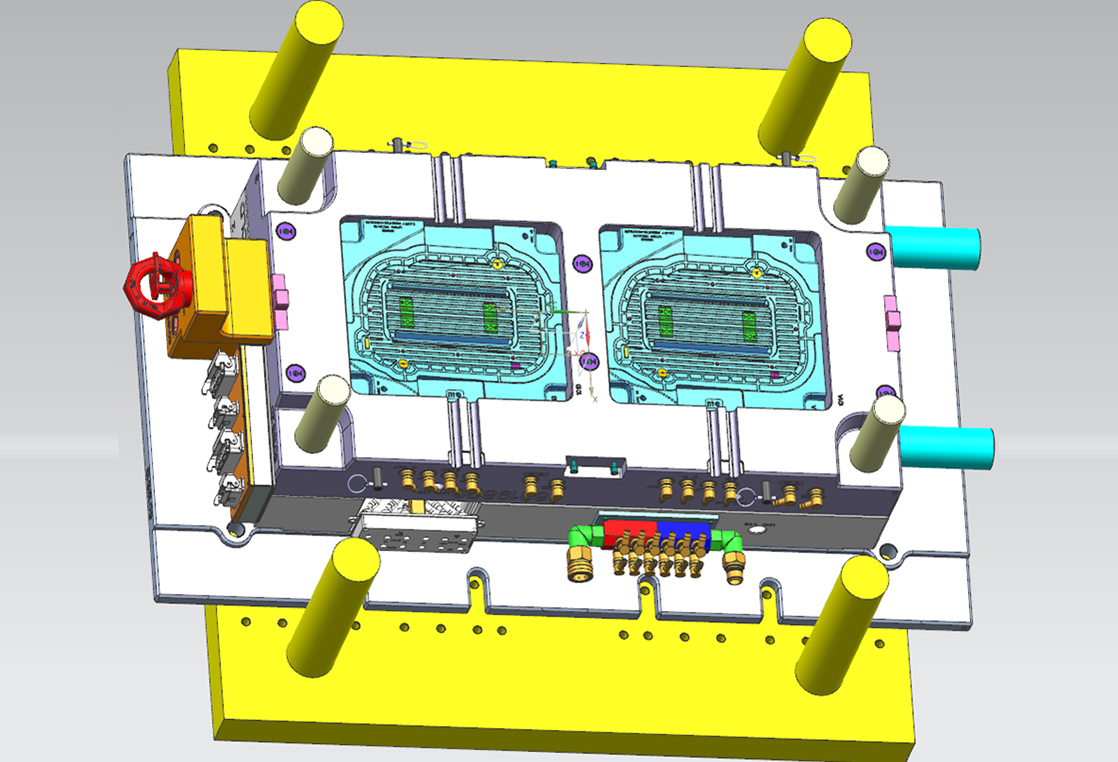

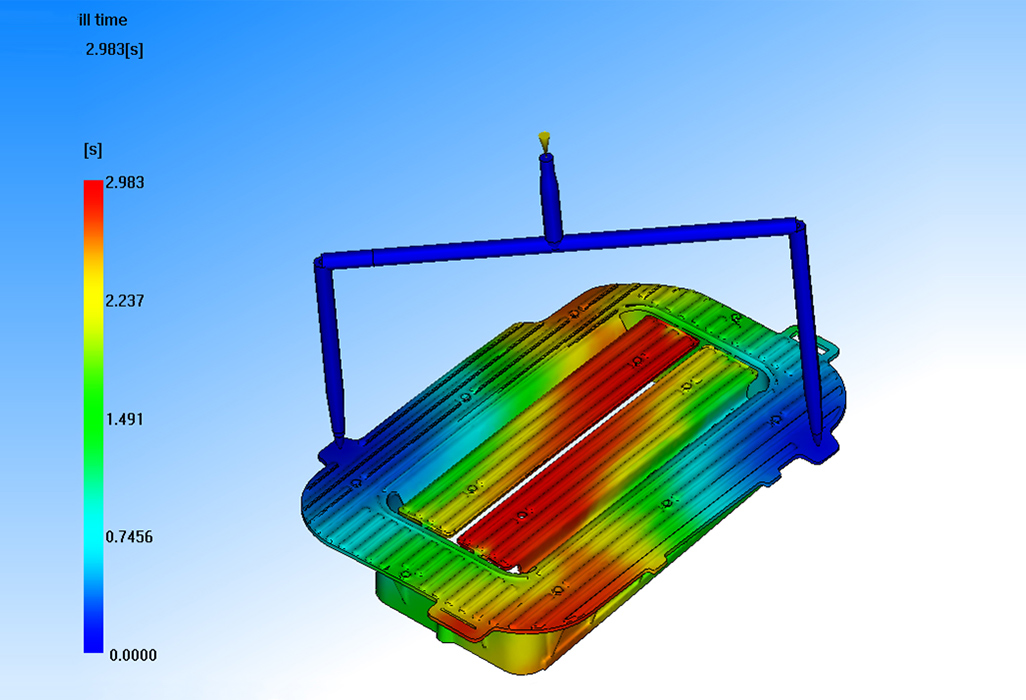

PAB Chute Soft

| Part Name:PAB Chute Soft | Part No:FC00AAZ411791 |

| Part Size:260x386x86mm | Mould Size:1700X1000X901mm |

| Insert Material:1.2738HH | Part Material:TEO |

| Cavity Number:1X2 | Injection system:4 drops valve gate HRS Hot nozzles |

| Quoted press machine:1000 Ton | Cycle time:58 sec |

| Design timing:2 Weeks | Manufacture time:11 Weeks |

| Manufature date:July 2017 |

|  |

|  |

|

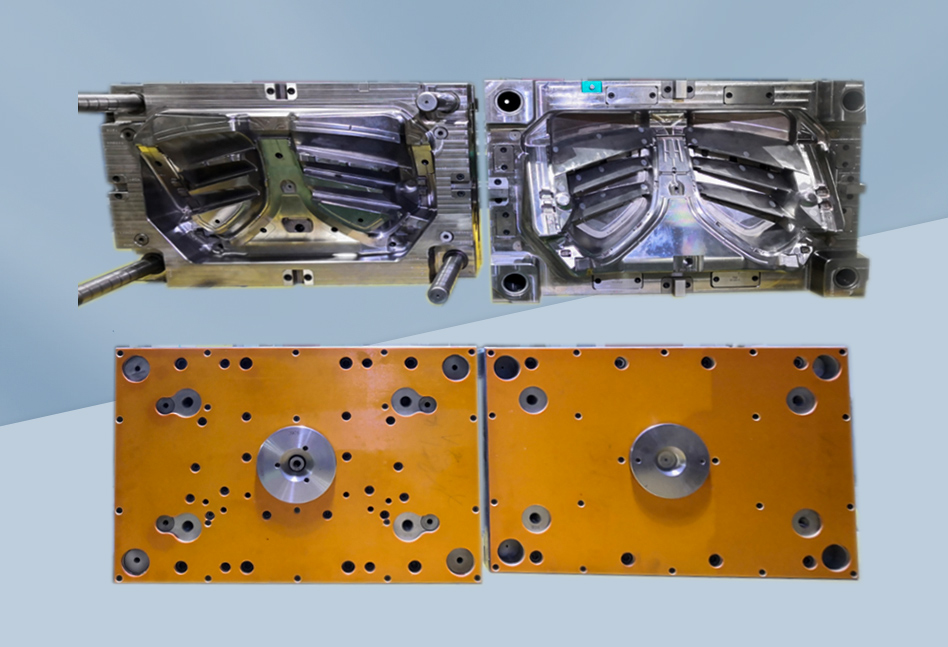

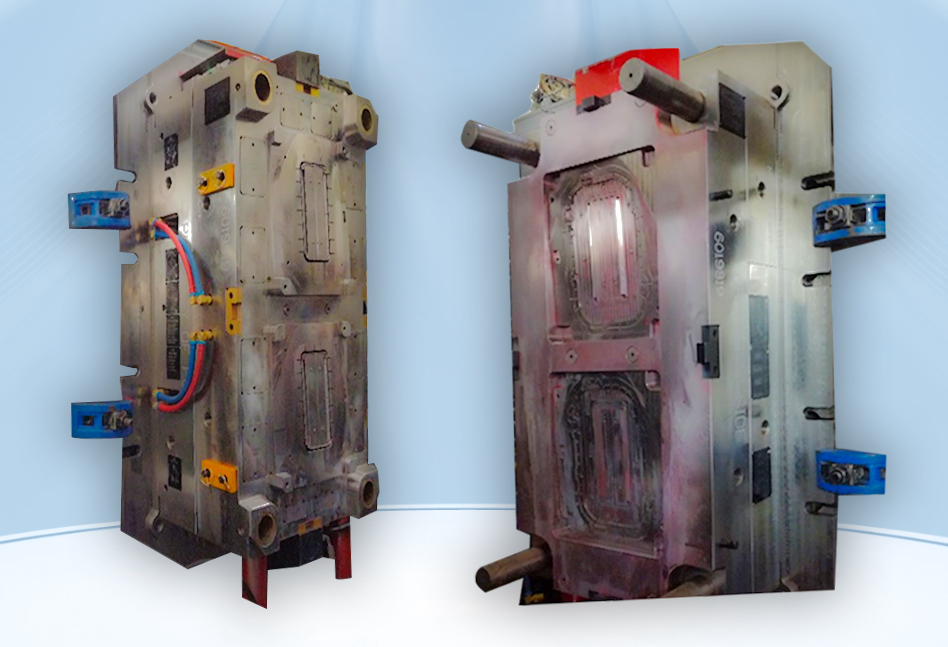

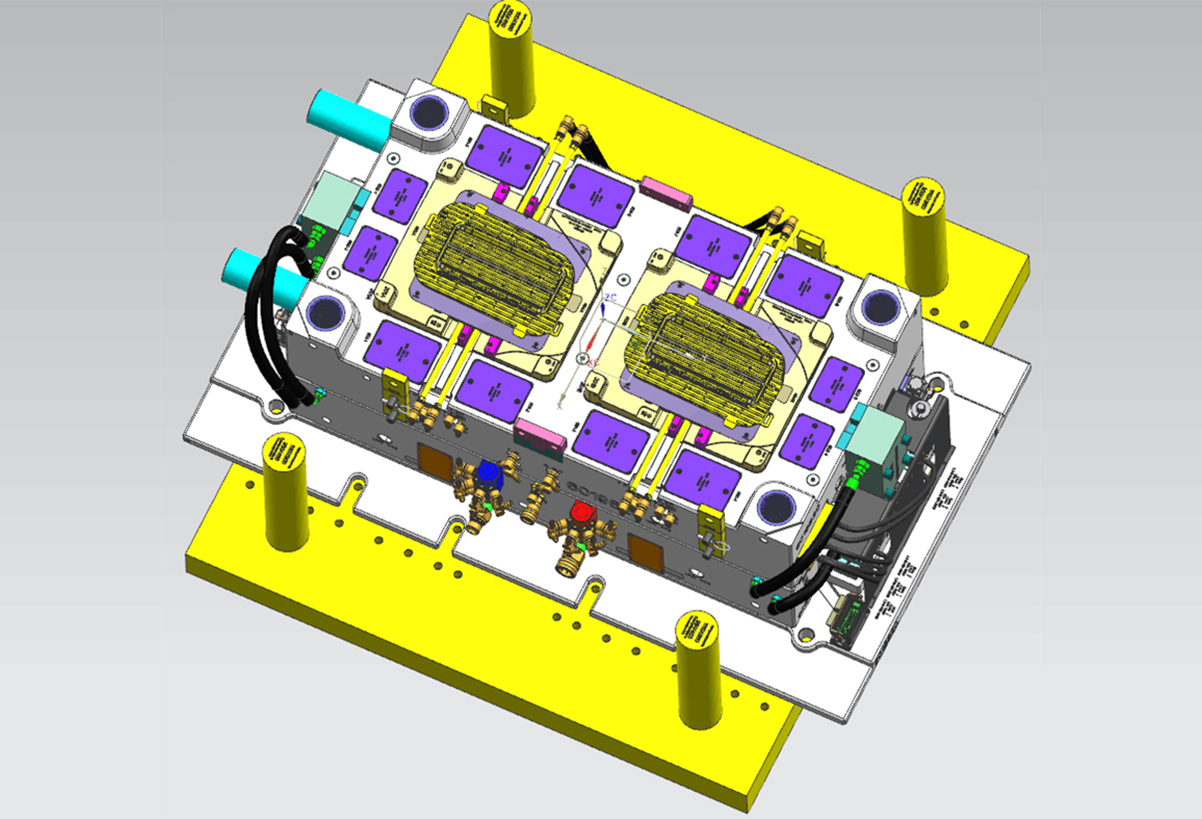

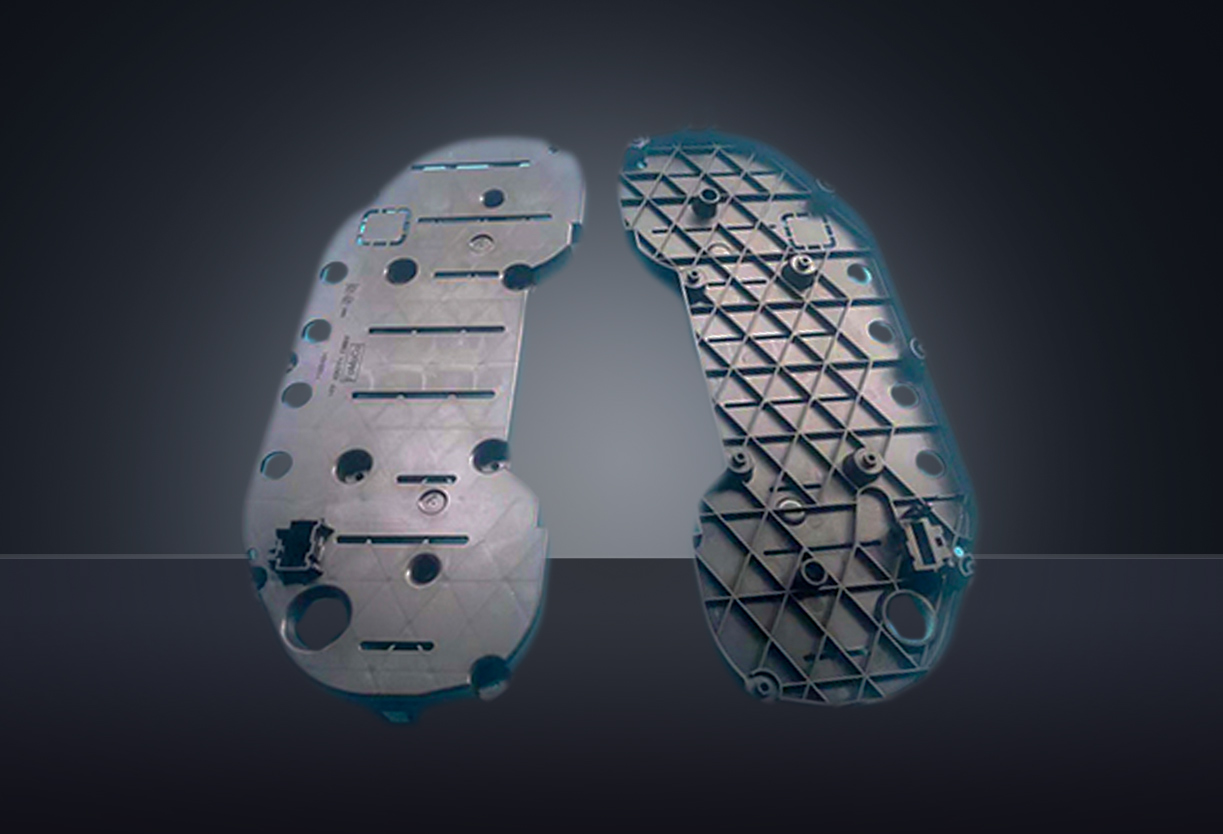

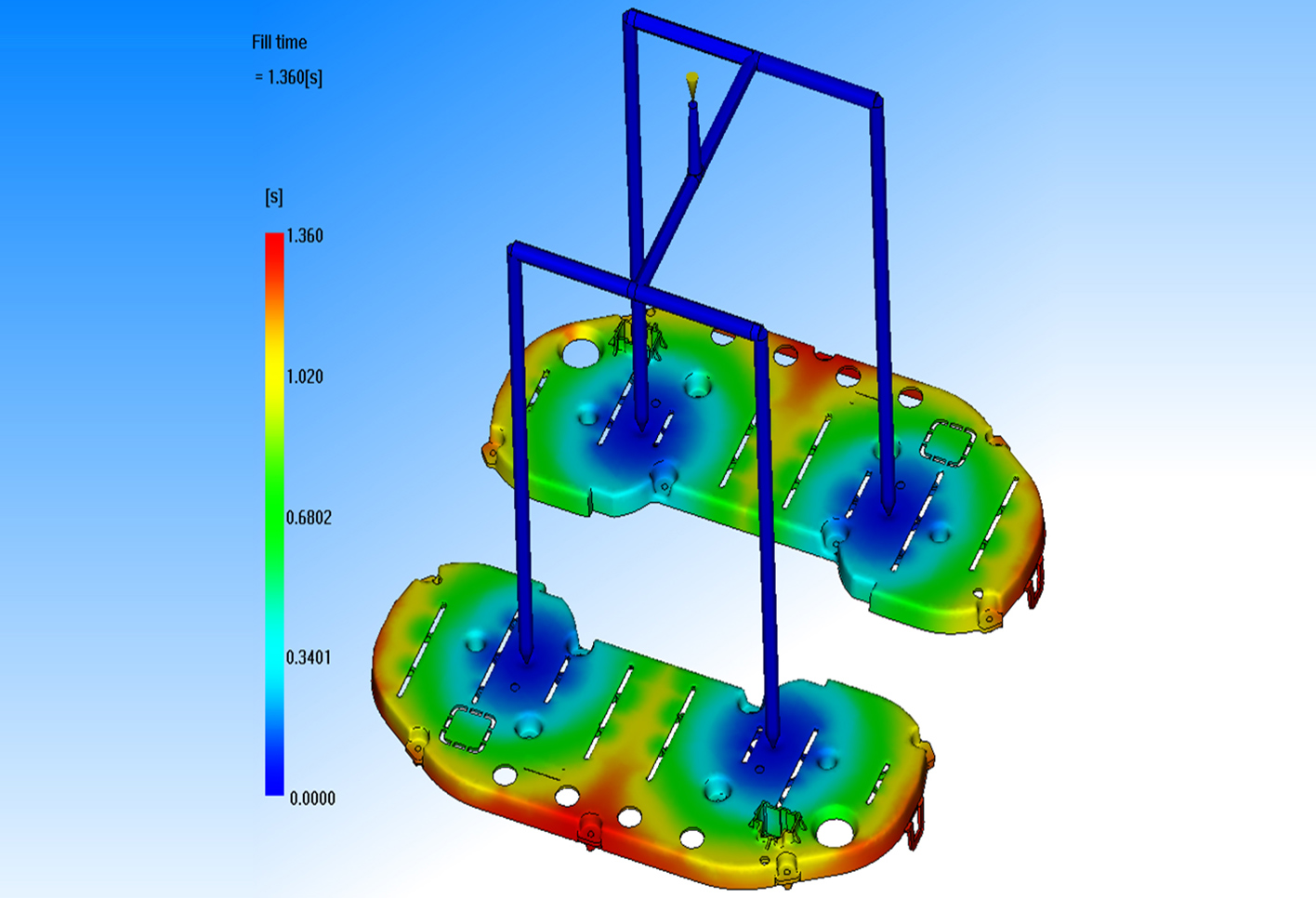

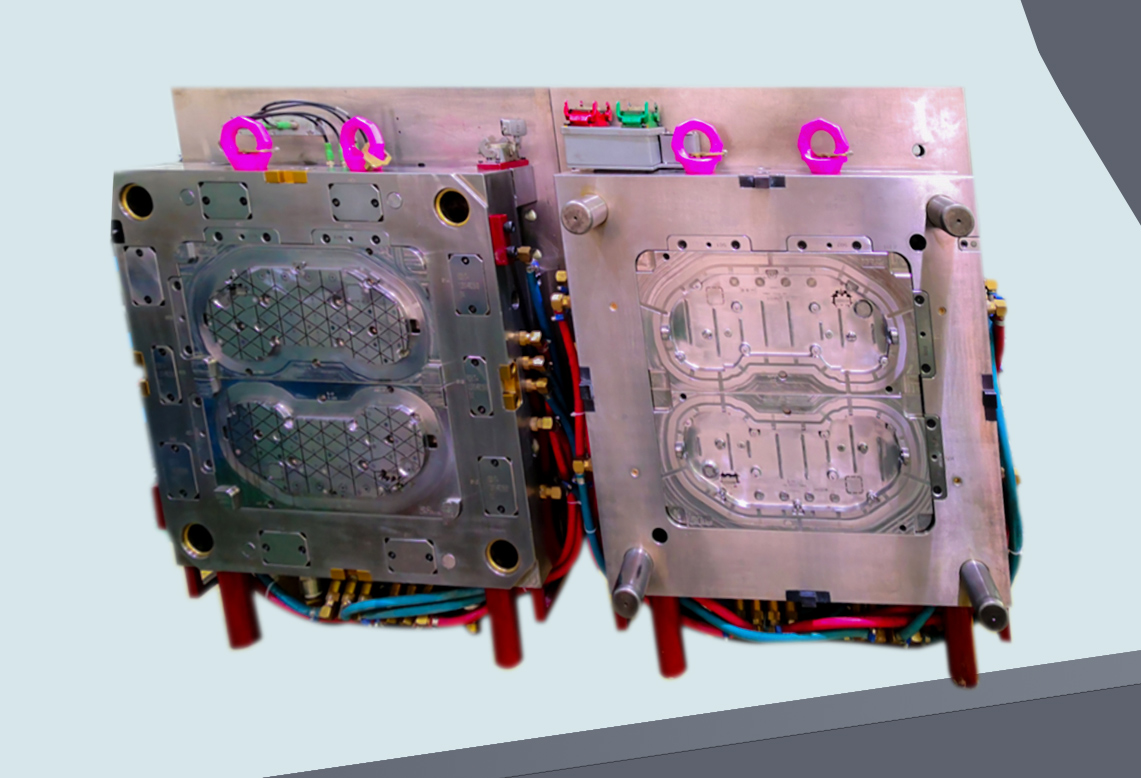

P702 L1 Rear Cover

| Part Name:P702 L1 Rear Cover | Part No:VPML3F-10A855-B |

| Part Size:162X370X39mm | Mould Size:1000X810X567mm |

| Insert Material:1.2344 | Part Material:PP-TD40% |

| Cavity Number:1X2 | Injection system:4 drops (Hot tips) HRS Hot nozzles |

| Quoted press machine:500Ton | Cycle time:47 sec |

| Design timing:2 Weeks | Manufacture time:6 Weeks |

| Manufature date:August 2018 |

|  |

|  |

|

Choose us

|

|

About Us

|

|

Our Factory

|

|

Capability

|

|

Case Study

|

|

Management

|

| COPYRIGHT @ LEMO MOULD (H.K)/(SHENZHEN) LIMITED ALL RIGHTS RESERVE

|

PRODUCTS

ABOUT US

CONTACT US

|